This post was originally published on here

Mavcor, a leader in the construction of facilities for this vital sector, has established itself as a key player by offering a blend of technical expertise, innovation, and collaboration to deliver high-quality, custom-built spaces.

Founded with a vision to turn complex projects into reality, Mavcor has earned a reputation for creating precise and flexible facilities for pharmaceutical and life sciences companies. From initial design to full-scale construction, it is the go-to partner for organizations looking to develop facilities that meet the stringent requirements of research, development, and production.

Nicholas Mucci, president of Mavcor, emphasizes the company’s approach: “We look at the big picture. We structure teams, coordinate supply chains, and guide all professionals toward a shared goal of delivering advanced facilities that meet both business objectives and regulatory standards.”

We are not just building facilities; we’re building the future of pharmaceutical and life sciences research.

This holistic view of project delivery ensures that every aspect of a facility’s design, construction, and functionality is aligned with the client’s overarching business and operational goals.

Comprehensive Approach to Project Management

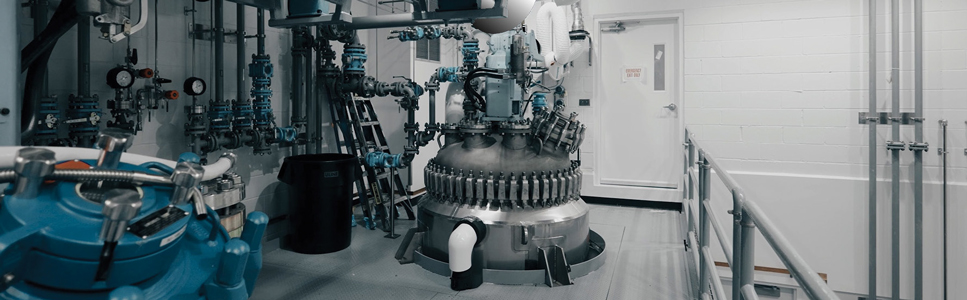

At the heart of Mavcor’s success is its ability to bring together the diverse elements required for a successful construction project: technical know-how, market insights, regulatory expertise, and a highly efficient supply chain. The company brings deep expertise in the delivery of GMP-ready life sciences facilities, supporting sterile manufacturing, packaging, and fill-finish operations across solid, liquid, and semi-solid dosage formats. Its experience spans a wide range of specialized facilities, including XP clean rooms, biosafety-level laboratories, and GMP-compliant production spaces, designed for testing, dispensing, mixing, processing, encapsulation, batching, and filling.

This includes environments purpose-built for sterile packaging and filling operations, such as solid dose packaging (tablet and powder filling into bottles, blisters, and sachets), liquid dose filling into bottles, vials, sachets, and FFS systems, and semi-solid filling into tubes, sachets, and jars. Manufacturing and processing spaces are delivered to support solid dose dispensing, granulation, compression, encapsulation, coating, and branding, as well as liquid and semi-solid dispensing, phase mixing, and multi-kettle or dual-kettle processing suites, all engineered to meet stringent GMP, contamination-control, and commercialization requirements. These are not ordinary facilities; they are the lifeblood of pharmaceutical innovation, where precise conditions are necessary for breakthroughs in drug development, clinical trials, and biotechnological research.

What truly sets Mavcor apart is its comprehensive approach to project management. The company manages all aspects of its clients’ projects, from budgeting and design coordination to construction management, ensuring that every detail is attended to with the utmost care. Throughout each phase of construction, Mavcor prioritizes its clients’ commercialization goals.

By aligning closely with design consultants and understanding the strategic design intent behind every project, Mavcor creates synergies that lead to faster, more cost-effective success. This collaboration between Mavcor, its clients, and external teams is integral to the company’s ability to provide tailored solutions that meet and often exceed expectations.

Highly Specialized and Nimble Supply Chain

Construction projects in the pharmaceutical and life sciences sectors are inherently complex. They frequently involve building highly specialized spaces such as clean rooms and controlled environments necessary for the development of new drugs or for biological research. These projects require a careful balance of cost, quality, and regulatory compliance, with every decision carrying significant consequences.

To meet these challenges, Mavcor has developed a method for integrating standardized products with customized solutions, ensuring that each project is executed efficiently whether it is a small-scale pilot facility or a full-scale GMP production plant on schedule.

-

We look at the big picture. We structure teams, coordinate supply chains, and guide all professionals toward a shared goal of delivering advanced facilities that meet both business objectives and regulatory standards.

This tight-knit network enables Mavcor to adapt quickly to the evolving needs of each project while maintaining full control over schedules and budgets. In an industry where delays or missteps can cost millions, Mavcor’s agility is a significant advantage.

Focusing on Value-Engineered Solutions

One of the company’s primary strengths is its ability to handle projects that involve rapid timelines and limited resources. Mavcor is often the first call for companies in need of infrastructure to support pilot projects for drug trials or biological research. These projects, often at the cutting edge of science, come with unique challenges including limited funding, tight timelines, and a lack of pre-existing infrastructure.

To address these challenges, Mavcor specializes in helping clients design and build facilities that are both functional and cost-effective. By focusing on value-engineered solutions, Mavcor delivers high-performance facilities while ensuring that projects remain within budget and meet clients’ goals for commercialization.

To address these challenges, Mavcor specializes in helping clients design and build facilities that are both functional and cost-effective. By focusing on value-engineered solutions, Mavcor delivers high-performance facilities while ensuring that projects remain within budget and meet clients’ goals for commercialization.

The company’s ability to complete projects on time and within budget is critical for its clients, who rely on these facilities to advance research and bring new products to market. Whether the project involves a research facility, a clinical trial center, or a biomanufacturing plant, Mavcor has the expertise to complete it efficiently and within the schedule requested by the customer.

A strong focus on regulatory compliance and operational standards ensures that every facility is built to withstand demanding conditions and undergoes thorough testing before being handed over to the client.

Delivering Projects with Precision/

Mavcor’s commitment to technology and innovation plays a major role in its ability to deliver projects with precision. The company employs advanced tools such as Building Information Modeling (BIM) to design and visualize facilities before construction begins. This 3D modeling technique enables the company to identify potential issues early and address them before they become costly problems.

Alongside BIM, Mavcor uses advanced project management software and real-time monitoring tools to track progress, optimize schedules, and ensure alignment among all stakeholders throughout the project’s lifecycle.

Alongside BIM, Mavcor uses advanced project management software and real-time monitoring tools to track progress, optimize schedules, and ensure alignment among all stakeholders throughout the project’s lifecycle.

This integrated approach to technology not only improves efficiency and quality but also strengthens collaboration among all parties involved. From architects and engineers to contractors and subcontractors, the entire team can access the most up-to-date project information, ensuring consistency and clarity across every phase. This level of coordination is especially vital in the pharmaceutical and life sciences sectors, where the stakes are high and the margin for error is minimal.

Flexible and Adaptable Project Delivery

Mavcor’s approach to project delivery is flexible and adaptable, ensuring the company can meet the unique needs of each client. The company offers several delivery options, including Design-Bid-Build, Design-Build, and Construction Management, with each model tailored to the specific needs of the client and project.

In the Design-Bid-Build model, Mavcor works with external design teams to create detailed plans before construction begins, ensuring that every step is meticulously planned and executed. This approach is ideal for projects requiring thorough documentation and rigorous oversight.

For clients looking for faster delivery, Mavcor offers a Design-Build model, in which the design and construction processes are integrated. In this model, Mavcor works closely with architects, engineers, and contractors from the outset, enabling quicker decision-making and faster completion. This streamlined approach allows clients to get their facilities operational as quickly as possible without sacrificing quality or compliance.

When project scopes are not fully defined, Mavcor offers a Construction Management model. This flexible approach allows clients to begin with the construction of a basic shell and add programming and services as the project evolves. Acting as an extension of the client’s team, Mavcor ensures that projects remain on track through clear communication and precise management at every stage. Regardless of the delivery model, Mavcor’s commitment to quality, collaboration, and client satisfaction remains constant.

Creating a Clear Structure for Risk Management

The company’s strength lies not only in its technical capabilities but also in its people. Mavcor’s team is composed of seasoned professionals who bring extensive experience and expertise to every project. From engineers and architects to project managers and construction specialists, the team is united in its goal of delivering facilities that support innovation and meet the highest standards of quality and compliance. The company invests heavily in staff development to ensure that team members remain at the forefront of industry trends and technological advancements.

Mavcor’s approach to risk management is another cornerstone of its success. The company places a strong emphasis on communication and collaboration, ensuring that potential risks are identified and addressed early before they can cause delays or cost overruns.

Mavcor’s approach to risk management is another cornerstone of its success. The company places a strong emphasis on communication and collaboration, ensuring that potential risks are identified and addressed early before they can cause delays or cost overruns.

By creating a clear risk management structure, Mavcor can quickly assess and resolve issues that arise during a project. This proactive approach not only ensures smooth delivery but also adds value for clients by minimizing disruptions and maintaining strict control over timelines and budgets.

Supporting the Next Generation of Medical Innovations

Looking ahead, Mavcor sees significant opportunity in new technologies, including artificial intelligence and advanced software. The company is already collaborating with software developers and AI providers to explore ways to optimize project delivery and enhance efficiency.

By embracing these emerging technologies, Mavcor aims to further streamline operations, reduce costs, and improve delivery times. This focus on innovation and continuous improvement ensures that the company remains at the forefront of the industry, prepared to tackle future challenges.

As Mucci puts it, “We are excited for where the industry is headed. There are significant opportunities for efficiency and productivity gains, and we are committed to exploring every option to stay ahead of the curve. We are not just building facilities, we are building the future of pharmaceutical and life sciences research.”