This post was originally published on here

KAIST scientists have created a fast-acting, stable powder hemostat that stops bleeding in one second and could significantly improve survival in combat and emergency medicine.

Severe blood loss remains the primary cause of death from combat injuries. To address this challenge, a research team at KAIST that included an active duty Army Major set out to develop a faster and more reliable way to stop bleeding.

Their work led to a next-generation powder-type hemostatic agent that can halt bleeding within one second when sprayed directly onto a wound, offering a potential breakthrough for saving lives on the battlefield.

A spray-on solution in seconds

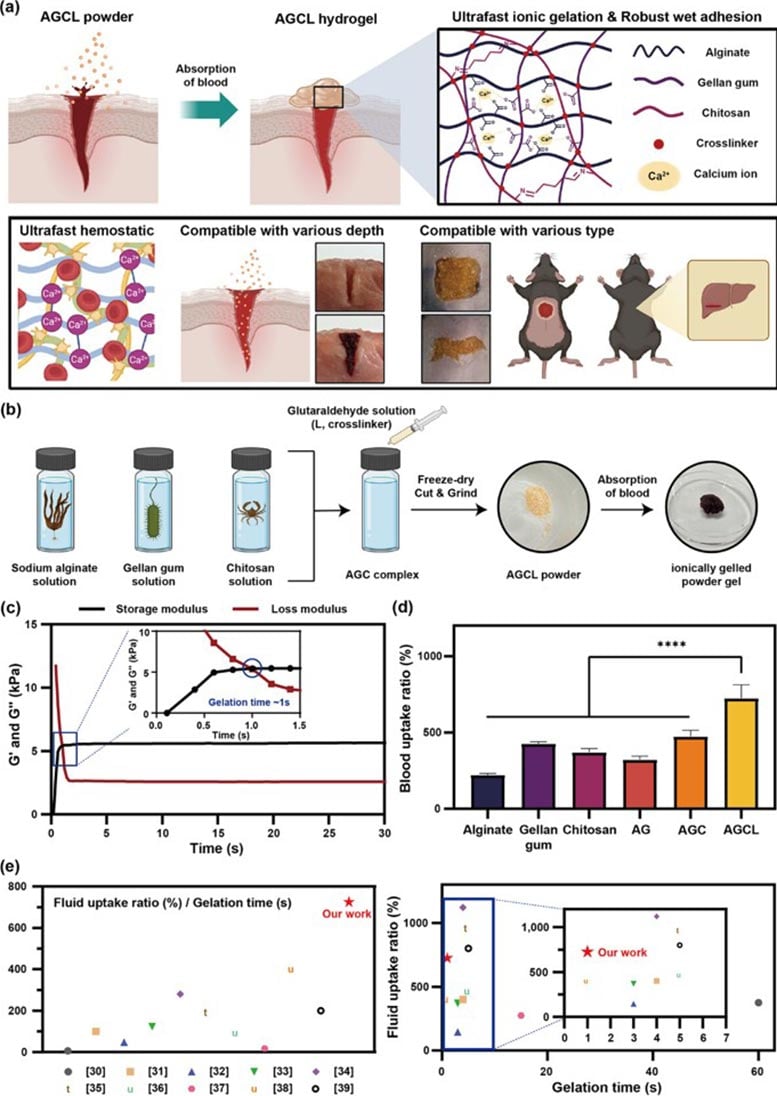

On December 29th, KAIST announced that a joint team led by Professor Steve Park of the Department of Materials Science and Engineering and Professor Sangyong Jon of the Department of Biological Sciences had created a powder based hemostatic agent that rapidly forms a strong hydrogel barrier. When applied to an injured area, the material transforms within about one second, sealing the wound almost immediately.

The researchers designed the technology with real combat conditions in mind, and the direct involvement of an Army Major helped ensure its practical readiness. The agent hardens instantly even in harsh environments such as battlefields and disaster zones, and its stability during storage allows it to be deployed quickly for emergency treatment.

Why existing hemostats fall short

Traditional patch-type hemostatic products commonly used in medicine struggle to treat deep or irregular wounds because of their flat shape. These materials are also sensitive to heat and moisture, which limits how easily they can be stored and used in demanding settings.

To overcome these limitations, the KAIST team developed the hemostatic agent in a powder form that can be applied to wounds of many shapes and sizes, including those that are deep or uneven. A single formulation can be used across a wide range of injury types, improving flexibility in emergency care.

Existing powder hemostatic agents had limits in hemostatic capability as they functioned by physically absorbing blood to form a barrier. To solve this problem, the research team focused on the ionic reactions within the blood.

The ‘AGCL powder’ developed this time has a structure that combines biocompatible natural materials such as Alginate and Gellan Gum (which react with calcium for ultra-fast gelation and physical sealing) and Chitosan (which bonds with blood components to enhance chemical and biological hemostasis). It reacts with cations such as calcium in the blood to turn into a gel state in one second, instantly sealing the wound.

Strength, safety, and regeneration

Furthermore, by forming a three-dimensional structure inside the powder, it can absorb blood amounting to more than 7 times its own weight (725%). Due to this, it quickly blocks blood flow even in high-pressure and excessive bleeding situations, and showed superior sealing performance compared to commercial hemostatic agents with a high adhesive strength of over ’40kPa’, a level of pressure that can withstand being pressed strongly by hand.

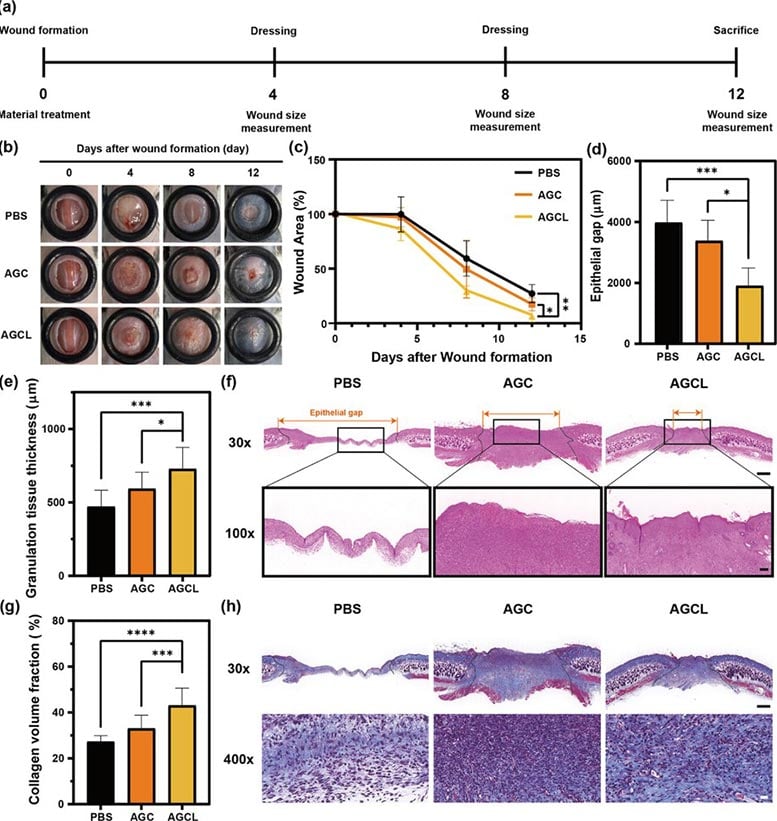

AGCL powder is composed entirely of naturally derived materials, showing a hemolysis rate of less than 3%, a cell viability rate of over 99%, and an antibacterial effect of 99.9%, making it safe even when in contact with blood. In animal experiments, excellent tissue regeneration effects such as rapid wound recovery and promotion of blood vessel and collagen regeneration were confirmed.

Proven performance under stress

In surgical liver injury experiments, the amount of bleeding and hemostasis time were significantly reduced compared to commercial hemostatic agents, and liver function recovered to normal levels two weeks after surgery. No abnormal findings were observed in systemic toxicity evaluations.

In particular, this hemostatic agent maintains its performance for two years even in room temperature and high humidity environments, possessing the advantage of being ready for immediate use in harsh environments such as military operation sites or disaster areas.

From defense research to civilian care

Although this research is an advanced new material technology developed with national defense purposes in mind, it has great potential for application throughout emergency medicine, including disaster sites, developing countries, and medically underserved areas.

It is evaluated as a representative spin-off case where national defense science and technology expanded to the private sector, as it is capable of everything from emergency treatment on the battlefield to internal surgical hemostasis.

Spin-off case: Expanding or transferring national defense science and technology for use in the private sector. Examples include computers, GPS, microwave ovens, etc.

This study was recognized for its scientific innovation and national defense utility simultaneously, winning the 2025 KAIST Q-Day President’s Award and the Minister of National Defense Award at the 2024 KAIST-KNDU National Defense Academic Conference.

Ph.D candidate Kyusoon Park (Army Major), who participated in the research, stated, “The core of modern warfare is minimizing the loss of human life,” and added, “I started the research with a sense of mission to save even one more soldier.” He continued, “I hope this technology will be used as a life-saving technology in both national defense and private medical fields.”

Reference: “An Ionic Gelation Powder for Ultrafast Hemostasis and Accelerated Wound Healing” by Youngju Son, Kyusoon Pak, Taehoon Lee, Monica Celine Prayogo, Jinyoung Choi, Sukkyung Kang, Minjoo Kang, Byungkook Oh, Sang Yu Sun, Sanha Kim, Sung Gap Im, Sangyong Jon and Steve Park, 28 October 2025, Advanced Functional Materials.

DOI: 10.1002/adfm.202523910

Support of the National Research Foundation of Korea (NRF).

Never miss a breakthrough: Join the SciTechDaily newsletter.

Follow us on Google and Google News.